Resilinc has today launched its global ‘Spotlight on Factory Fires’ report. The report, which uses Resilinc’s unique Eventwatch monitoring system, found that the UK was the sixth most affected country by an increase in factory fires in 2021.

Furthermore, Resilinc added that more alerts for factory fires were sent out globally from its Eventwatch monitoring system in Q3 of 2022 than in the whole of 2021.

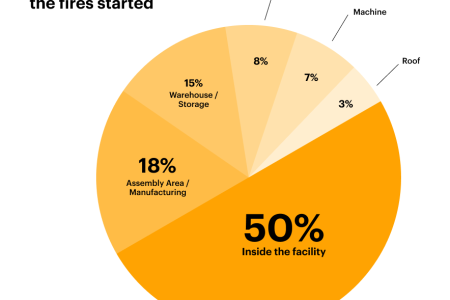

This leaves businesses in a precarious position, with over half of all fires being caused by faulty equipment and machinery (59%). The second-highest cause of fires was flammable liquids and gases (18%), followed by electrical lighting and equipment (10%), human error (4%), hot work/welding (3%) and combustible dust (3%). Worryingly, of fires that did start in the assembly/manufacturing area just 11% activated the sprinklers, with 9% of fires causing factory downtime of over four weeks.

When equipment and machinery are incorrectly installed, operated or maintained, fire risk continues to grow through an absence of proper safety, cleaning and maintenance procedures. A contributing factor to this is a shortage of skilled labour with employees insufficiently trained and not spotting potential risks. Other gaps around processes and component shortages were also cited in the report.

The impact of these fires should not be understated, with 47% causing a medium level of damage or higher. In addition to the cost of repairs and damage itself, there is a substantial cost in lost business and output while the factory isn’t operational. Not to mention a significant impact on the supply chain, with organisations relying on the factory impacted by the fire for critical parts and goods which it’s suddenly not able to fulfil.

“The increase in factory fires is a worrying development because of the ripple effect it causes to the whole supply chain. One of the examples in our Factory Fires report that really brings this home is a three-day fire at a semiconductor plant in Japan which shut production lines down for six months,” said Bindiya Vakil, Founder and CEO, Resilinc. “This sent procurement teams scrambling and the price of some chips went from $5 to $110 in a matter of days, ultimately costing sourcing organisations tens of millions of dollars. A supplier risk assessment later revealed that the site didn’t have automatic sprinklers or a fire suppression system which contributed hugely to its voracity.”

“Clearly an increase in the cost of vital parts produced by your supply chain should a supplier suddenly be unable to fulfil your requirements could be hugely damaging to your own business. This is where the need to multi-tier map and monitor your suppliers properly becomes crucial. Imagine if one or more businesses had identified the fire risk at the Japanese chip producers? Numerous businesses in that supply chain could have saved themselves millions of dollars in unanticipated costs.” Vakil added.

Resilinc’s ‘Spotlight on Factory Fires’ report recommends a combination of mapping, risk assessments and monitoring to help organisation’s avoid undetected fire risk in their supply chain. The full report can be downloaded here.

To read more news and exclusive features see our latest issue here.

Never miss a story… Follow us on:

![]() International Fire Buyer

International Fire Buyer

![]() @Firebuyer

@Firebuyer

![]() Fire Buyer

Fire Buyer

Media Contact

Louis Curtis

Editor, International Fire Buyer

Tel: +44 (0) 1622 823 922

Email: editor@firebuyer.com