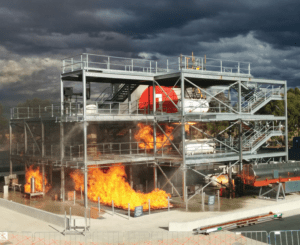

In this exclusive Ask the Expert, Rebecca Spayne of Fire Buyer catches up with Andreas Schick, Sales Specialist, Robotics, Magirus to discuss robotics and the company’s 160th anniversary Congratulations! Magirus is celebrating a significant milestone with its 160th anniversary and honouring the 200th birthday of its founder, Conrad Magirus. Can you share with us a bit about the company’s rich history and heritage and how it has influenced its current innovations? Yes, certainly. Thank you for your congratulations. Conrad Dietrich Magirus was truly innovative in his era, always ready to take significant risks and venture into completely new territories. Take, for example, the introduction of the first mobile ladder in 1873, a major innovation at the time. This innovative spirit has been preserved throughout the years, as we continue to explore new paths and bring fresh innovations to the market. As a leading manufacturer of firefighting vehicles and equipment, we strive to be pioneers and leaders in the market, which has led us to embrace the field of robotics. Robotics technology in firefighting has made notable advances recently. Could you detail the primary benefits that robots offer to firefighting, especially regarding enhancing safety and operational effectiveness? Looking at today’s firefighting methods, there is a sense that many aspects have not evolved much over the past 50 years. While this might sound contentious, it’s apparent when you see that firefighters are still directly confronting fires, much like decades ago. Though today’s firefighters are equipped with state-of-the-art vehicles and better technology, they still face significant risks. Nowadays, we can keep firefighters out of immediate danger by employing robots to combat fires. Beyond safety, there is also the issue of reducing the physical burden on firefighters. Carrying heavy equipment like pumps, fans, hoses, and hydraulic tools is incredibly strenuous. Robots can now handle these tasks, alleviating the need for firefighters to transport this equipment manually. In the realm of firefighting, where swift decision-making and accuracy are vital, how do robots enhance response times and decision-making precision in critical situations? How does this influence the overall efficacy of firefighting missions? On one side, commanders can make quicker decisions with robots available. It’s invariably safer and more straightforward to dispatch a robot into risky environments like a tunnel at risk of collapse or a hazardous industrial building than to send in human personnel. Moreover, our robots are outfitted with camera systems, which are utilised primarily for reconnaissance. This capability allows for faster assessment of situations, enabling quicker and more informed decision-making. Lastly, with advanced equipment like the TAF or Wolf R1, we can apply water more strategically and efficiently, thereby extinguishing fires more rapidly than with traditional methods. Regarding your two flagship products, the AirCore TAF and the Wolf R1, both represent significant advancements in firefighting technology. Could you elaborate a bit on the concept behind integrating such advanced robots into firefighting? As I mentioned before, the primary goal is to protect and support firefighters, not to replace them. It’s crucial to understand that the machines are there to assist, not to take over their roles. The firefighters remain in control, making critical decisions while the robots provide support. Although the Wolf R1 and the AirCore TAF serve different functions, their core objective is the same: to enhance firefighter safety and efficiency. The AirCore TAF, known for its multifunctional use, varies from extinguishing fires with water and foam to providing logistic support and vehicle rescue. How does this versatility impact firefighting operations? Certainly, there’s a lot to cover, but I’ll highlight the key points. The term TAF stands for Turbine Aided Firefighting. We utilise a turbine to deploy a very fine water mist to extinguish fires. Our goal here is to use water as efficiently as possible. Whether you have 300 or 400 litres per minute available or need to scale up to 6000 litres per minute, the turbine can handle it. This flexibility is key, and we employ a very fine mist—tiny water droplets delivered not with high pressure, but efficiently at a lower pressure, maybe around three bar or slightly more. The concept is designed to extend the duration the water mist remains airborne, thereby enlarging the water’s surface area. This efficiency allows us to propel the mist up to 60 metres using just the airflow from the turbine. Additionally, we can use a standard monitor for a reach of about 18 metres. The TAF’s multifunctionality doesn’t stop there; we can employ the turbine solely for ventilation, removing smoke from buildings or assisting with logistics. In addition, a camera system, including thermal imaging, is mounted atop the TAF, enabling the exploration of areas and identification of hotspots. The TAF is indeed substantial, weighing around four tons, yet this heft translates to a robust pulling force of about 3.8 tonnes, ensuring it can clear almost any obstacle. This feature is particularly useful in scenarios like extracting burning electric vehicles from underground parking, where the TAF’s height, under two meters, proves advantageous, allowing it to access and address fires in tight spaces and even remove vehicles if necessary… To read more exclusive articles and latest news, see our last issue here. Never miss a story… Follow us on: International Fire Buyer @Firebuyer Fire Buyer Media Contact Rebecca Spayne Managing Editor, International Fire Buyer Tel: +44 (0) 1622 823 920 Email: [email protected]