Trident emergency products increase its Titan foam pump offerings and introduces complete pump & motor packages

Trident have been developing the Titan line of rotary gear, positive displacement foam pumps for fixed foam system applications, mobile apparatus foam systems and medium pressure water mist systems. Titan pumps have reportedly been specially designed with features and benefits found nowhere else. Manufacturers reviewed the good and the bad of many foam pumps on the market today and developed the Titan line to provide superior performance and longevity. All of the pump models were created around the same features:

- All-bronze pump bodies, heads, and rotors.

- Heat treated 17-4PH stainless steel pump shafts for excellent corrosion resistance and superior rotor/shaft support.

- Silicon carbide mechanical pump seals prevent foam from contacting pump shafts, eliminating the shaft corrosion and pitting that leads to our competitors’ leaky lip seals.

- Sealed, double row spherical roller bearings provide superior rotor/shaft support and eliminate routine lubrication maintenance.

- No axial float eliminates side contact and rubbing wear.

- Splash oil lubricated timing gear drive system prevents rotor-to-rotor contact, rotor wear and heat build-up. This drive system increases efficiency and allows for extended periods of dry running.

- Square EPDM sealing rings between the body and heads provide superior sealing over standard paper gaskets. All pumps are assembled with stainless steel fasteners.

- Compatible with any type of foam concentrate and rated to a working pressure of 300 PSI (20.7 BAR). Foam system calibration, testing and training can be done with water at full pressure, eliminating expensive foam concentrates and ground contamination.

- Power sources include electric, diesel/gasoline engines, or PTO drives; water or hydraulic motors.

The pump design allows for very close machining tolerances providing increased pump efficiencies versus our competitors. This increased efficiency provides significant cost savings by lowering the power requirements (HP) of the power source.

Trident offers a full line of Titan pumps ranging from 30 GPM (115 LPM) to 500 GPM (1890 LPM) – all self-priming. All models are designed and built in accordance with NFPA 20 Standard for the Installation of Stationary Pumps for Fire Protection and NFPA 1901 Standard for Automotive Fire Apparatus. Five models are UL Listed in accordance with UL Standard 448C Stationary, Rotary Gear Type, Positive-Displacement Pumps for Fire Protection Service.

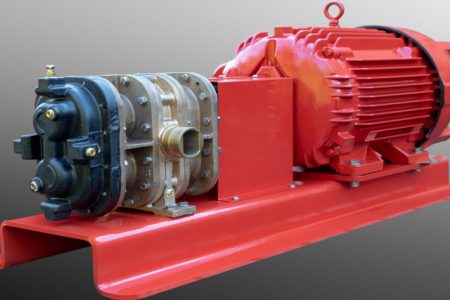

In conjunction with their UL Listed foam pumps, Trident offer electric motor driven pump packages mounted on a steel base frame. Customers need only to provide their foam system requirements and they will provide a quotation and data package.

Visit Trident at Intersec 2019, Stand 3-E32, to see the cut-away model and high-performance designs of our Titan foam pump – exclusively designed for the rugged 21st century firefighting industry.

www.tridentdirect.com