Women Talking Fire Firefighting Awareness Day with FRS

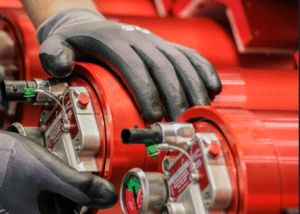

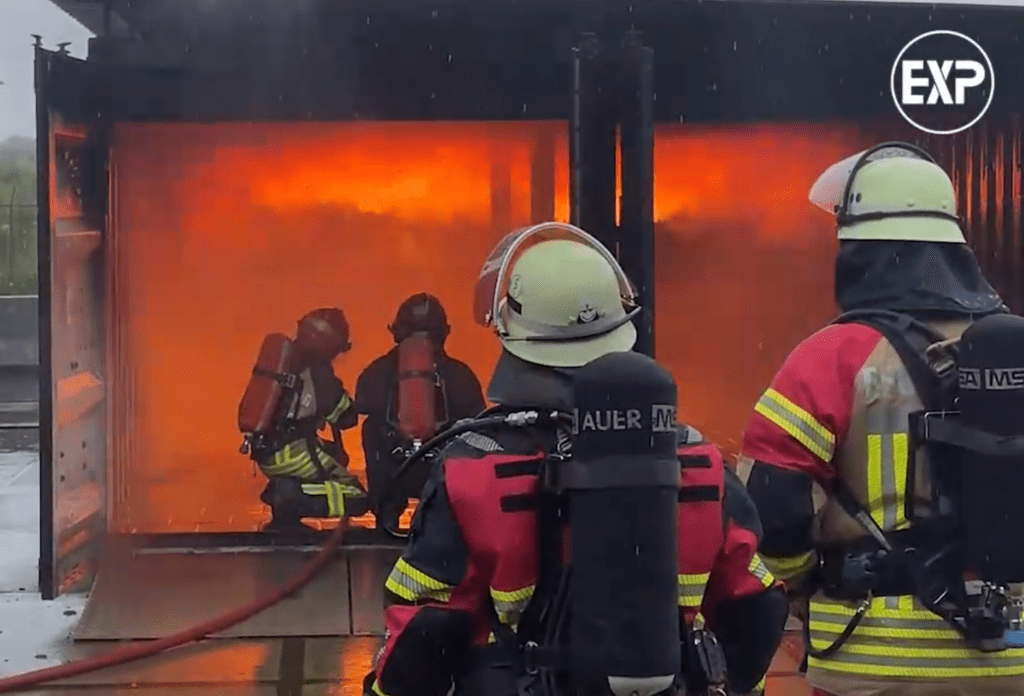

On 3 September 2024, Women Talking Fire and Cheshire Fire & Rescue Service hosted 50 delegates to the CFRS Training Centre for a practical and hands-on firefighting awareness day. After an initial welcome from Chief Fire Officer, Alex Waller, delegates divided into groups to spend the day visiting 5 different stations and finding out more about various aspects of firefighting. The stations included learning about: The equipment carried on a fire appliance How water supplies are obtained from both hydrants and open water sources The physical demands of firefighting, including undergoing the fitness tests that firefighters must pass High rise firefighting, including updated processes and procedures following the Grenfell Phase 1 report’s publication The Incident Command Centre – a fantastic interactive facility where incidents can be simulated and role playing can be used to teach and assess officers The day ended with a “big burn”, where delegates watched these various aspects put into practice as firefighters carried out a demonstration, rescuing individuals from a terraced house on fire. Women Talking Fire would like to thank the staff of Cheshire Fire & Rescue Service, and in particular Kristian Clowes, for hosting such a well-organised, interactive and informative day. After the success of our first collaboration, we are currently in discussions with CFRS about holding another event in the future. Feedback from delegates: “The whole event was excellent”. “The organisation of the whole day was exceptional – the Fire Service had been great!” “Brilliant!” “As a woman, it was great to attend an industry event where I was not in the minority”. Our First Year In its first year, Women Talking Fire has: Held a Technical Conference for 150 delegates in Leeds Held social evening events in London and Bury Undertaken a survey to better understand the views and perspectives of men and women working in the UK fire safety industry Collaborated with The Fire Safety Event 2024 Plans for the Next Year Women Talking Fire is planning: A workshop around confidence, communication and career progression workshop – to be held at the ASFP Academy, Coventry, on 6 March 2025 We hope to hold another firefighting awareness day with Cheshire Fire & Rescue Service We’ll continue to develop stronger partnerships with industry exhibitions, including Fire Buyer, London Build 2024, Firex 2024 and The Fire Safety Event 2025 Confidence, Communication and Career Progression Workshop Women Talking Fire are holding this workshop on 6 March 2025 at the ASFP Academy, Coventry. This interactive workshop is an opportunity to learn some practical skills and gain some actionable strategies for professional advancement. We want delegates to be empowered to have more impact when communicating, and to raise their personal brand to help them reach their full potential. We are delighted that Business Leader and Executive Coach Manjit Mandeir will be running the sessions. We’re grateful to the Association of Specialist Fire Protection for supporting us by providing the venue for this event. To read the full article, see our last issue here. Never miss a story… Follow us on: International Fire Buyer @Firebuyer Fire Buyer Media Contact Rebecca Spayne Managing Editor, International Fire Buyer Tel: +44 (0) 1622 823 920 Email: [email protected]

Women Talking Fire Firefighting Awareness Day with FRS Read More »