Fire Buyer looks at the different types of fire monitor technology available currently in the market and how these help different hazardous environments

Fire monitors are industrial monitor devices used to deliver large water flows for fire fighting purposes in high risk or hazardous industries. Industrial fixed monitors can be controlled automatically by means of a remote control station. Fixed Monitors are generally designed for heavy duty applications such as aggressive chemicals plants or offshore platforms. These heavy duty fire monitors are designed to withstand extreme conditions and are very robust and easy to maintain.

Portable monitors are devices used to deliver large water flows for fire fighting purposes in high risk or hazardous industries. Industrial portable monitors are used by private industrial fire professionals to protect high risk environments. Industrial fire protection equipment products cover heavy duty fire nozzles, rim seal floating roof tank fire protection systems and industrial fire suppression systems.

Automatic monitors are devices used to deliver large amounts of water or water/foam solution to remote targets. These monitors can be controlled manually via local mechanisms or automatically by means of actuators and remote control stations.

Most monitors are available with a full bronze body suitable for heavy duty applications such as aggressive chemicals plants or offshore platforms. Every piece should be designed to withstand extreme conditions granting a very long product lifetime. In this respect the variety of special materials or surface treatments makes this equipment very robust. Depending on the application the monitors can be equipped with jet/fog nozzles or branch pipes designed for water and water/foam solution.

The automatic movements on the horizontal and the vertical plane as well as the stream control (jet/fog) can be provided with hydraulic, electrohydraulic or electric actuators. Every monitor is designed to be controlled either manually or by remote controls available on a fixed or mobile wireless control station. The control stations are designed according to client specifications and may be manufactured for either hydraulic or electric actuators. Also the electric consoles may be equipped with PLC, achieving complete stand alone fire fighting systems, or can integrate accessories such as lightweight portable wireless consoles. Systems interconnections may be designed traditionally or with modbus redundant serial link (only for electric monitors) that allows sensible saving of system’s cables quantity requirements. All components, such as monitors and consoles, are available for hazardous areas installation in compliance with ATEX 94/9/CE Directive.

Technology

The SA Fire Niagara series fire fighting monitor represents one of the most advanced automatic monitors available nowadays for the fire industry. The monitor is designed to withstand extreme harsh and adverse environmental conditions offering to designers durable Bronze and Aluminium Bronze castings with waterways ranging from 3” to 6”. The monitors are ideal for high demanding installations such as jettys, harbours, refineries, chemical and offshore installations. The Niagara is available as an automatic monitor with a selection of three controls: hydraulic, electric and electro-hydraulic. The hydraulic Niagara is the traditional configuration of remote controlled monitors. It requires a hydraulic power pack that pumps oil into different metallic tubes. Each tube drives a movement of the hydraulic actuator governing the monitor movement. For each hydraulic actuator SA always includes an emergency hand-wheel for each movement that is used locally to take over the main power transmission.

An evolution of the Niagara is the electro-hydraulic series. These fire monitors are delivered with the hydraulic power pack installed underneath the monitor itself forming a unique standalone package that offers the electrical interface to the remote control panel and the hydraulic interface to the monitor actuators. This configuration allows for installation using electrical wiring from the control panel up to the hydraulic power pack, limiting the hydraulic tubing to a very short final interconnection. The absence of metallic tubing required in traditional hydraulic installation is appreciated in terms of lower installation and maintenance cost. Both hydraulic and electrohydraulic Niagara can rotate on the horizontal plane for 360° stop to stop. For both a special version of horizontal joint G/360 allows the monitor to rotate continuously. Those monitors are often preferred for installations where protection of multiple targets is required.

The other configuration of the Niagara monitor is electrical. A configuration that is achieved using electric actuators located on each monitor joint offering the maximum achievable remote control precision in the monitor movements. The electric monitors can be controlled by simple remote control stations or by programmable logic controllers PLC. In such cases the systems can be built implementing additional software features and reliability parameters that allows for SIL 2 compliant automatic monitor packages.

Depending on the application and fire fighting purpose, the terminal to be coupled to the monitor may be selected among nozzles for Jet/Fog stream, water cannons or foam branch pipes. The nozzles are the only solution that will include a control, whereas water cannons and foam branch pipes are normally fixed. Only in some cases an automatic deflector is added to foam branch pipes. SA Fire Protection offers a range of discharge options to achieve flow rates up to 20.000 L/min when used with the largest Niagara 6”. Independently from the controls used, the nozzles are designed for high performance and reliability and therefore are equipped with corrosion resistant materials and sand storm protector.

Platforms

Automatic monitors are often selected to protect marine terminals or refining installations where it is required to approach the fire from a certain height above ground. In this respect, organisations can use self standing modular designed structures that may be used to set up monitors at the highest level above protected targets. The structure can be manufactured in modules and designed for easy erection on site. A turret comes together with all accessories, such as external cooling system, internal main feeder, base valves and external ladder. The top of the turret may be equipped with a rotating platform that moves on the horizontal plane together with the automatic monitor. Mechanical connections from the monitor to the turret are built in the Niagara monitor body making the installation easy and straightforward. Below the turret, service controls for monitor enabling and disabling are available for maintenance operators. This is in order to safeguard them from being hurt by any erroneous remote operation that may come from ground stations. The rotating platform on top may be provided with 360° rotation, allowing monitors to move freely on the whole horizontal plane.

Remote actuation:

Monitor control panels are used to provide commands and signal position and status of automatic monitors. There are various possible panel configurations depending on system architecture, communication protocol and classification of the installation area. Usually, the fixed stations are manufactured with one, two or three monitor controls together with their water and foam control valves. For each monitor the panel is equipped with a joystick for horizontal and vertical monitor movements, a joystick for stream control (jet/fog) and two couples of push buttons for water and foam control valves. These consoles can be used to control either electric or electro-hydraulic monitors. Larger and complex control panels can be designed to host a PLC and control electrical monitors using a serial communication protocol. This solution is based on a redundant communication link and also allows system programming that provides fully automatic installations. The same technology may be used to design multiple control stations or to manage one or more wireless monitor consoles. Dedicated visualisation software is also available for specific control room requirements.

Wireless mobile control stations

Wireless mobile control stations, like Monix, are designed to control one or more monitors. The Monix console forms part of a main PLC based control system where the wireless module is integrated. The Monix consoles are normally kept on site in custom built boxes where they are connected to their battery charger and controller. When needed, the operator can activate the Monix and wear the portable console. The monitor selection is made by simply selecting the monitor with the frequency selector. Once the monitor is selected, the operator is capable of taking control by simply operating the joystick and the open/close buttons for the control valves. To switch to another monitor, one can simply rotate the selector switch and take control.

Manual firefighting monitors

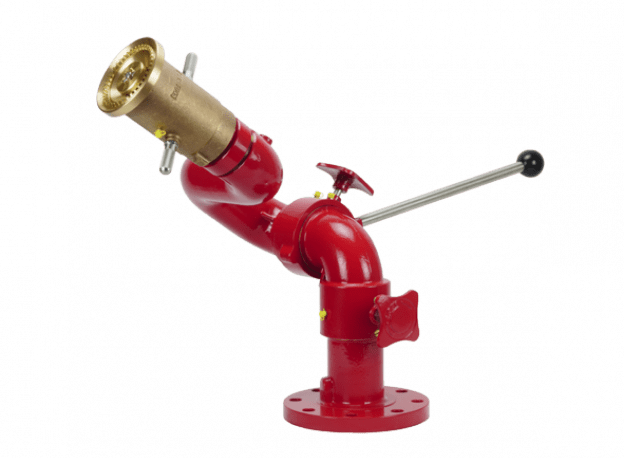

Manual Monitors are hand operated devices used to fight fires which require large amounts of water or water/foam solution to be delivered to remote targets. Every monitor is designed to be easily operated through its commands, requiring very little force by the operator even when adjusted during operation. The Monitor Bodies are available in Bronze or Stainless Steel for installation within industrial harsh environments. Each piece is designed and manufactured with extreme care to be robust and grant a long service life in adverse environmental conditions. Depending on the application, manual monitors can be equipped with nozzles or branch pipes capable of discharging water or water/foam solution. Nozzle and foam branch pipes are also available with a built in inductor that allows water and foam proportioning before discharge. Each monitor can be coupled to a large variety of accessories such as self oscillating units, hydrant supports, nozzles and branch pipes.

The requirement for automated firefighting is continuously increasing. Remote-controlled monitors, especially in combination with automated fire detection, allow a targeted but flexible firefighting operation in limited areas. The technical development in the field of drive engineering, sensor technology and control technology offers some great future potential.

Commentary: Frank Preiss is Managing Director of FireDos

Commentary: Frank Preiss is Managing Director of FireDos

The requirement for automated firefighting is continuously increasing. Remote-controlled monitors, especially in combination with automated fire detection, allow a targeted but flexible firefighting operation in limited areas. The technical development in the field of drive engineering, sensor technology and control technology offers some great future potential.

The big range of monitors and the possibility to select from a variety of mountable nozzles provide flexibility and enhance performance to achieve effective fire protection for high risk areas. Remote-controlled monitors allow a targeted firefighting operation in confined spaces and can be used for extinguishing agents like water, low-expansion foam and, if required, even powder. The nozzles are fine-tuned to suit the type of extinguishing agent, allowing extended reach. Combined with a suitable fire detection and control, effective fire protection can be guaranteed while requiring just a minimum number of firefighting personnel. To fully utilise the range of potential offered by remote-controlled monitors for firefighting, introducing a programmable (PLC) control system with state of the art communication facilities is mandatory. This allows the connection with automatic fire detection systems and fire alarm control panels also for very large and complex facilities. The response times are as fast as known from present automatic firefighting systems.

The technical development in the field of drive engineering, sensor technology and control technology offers some great future potential to detect fires in their initial phase as well as to fight fires in a localised and resource-conserving manner by use of monitors. In addition, a focus must be placed on what firefighters around the world use to fight fires. In live operations, the extinguishing agent flow is adapted to the requirements set by the fire incident. The availability of remote-controlled monitors and nozzles where the extinguishing agent flow rate can be adjusted by remote-control without interruption of the operation makes it possible to apply this procedure also to automated firefighting systems. If it is therefore successful to apply experience and procedures from practical firefighting to automated firefighting systems, the seeming paradox of “less extinguishing agent leads to a higher level of fire protection” can become reality.

Commentary: Mattias Eggert, Managing Director, Unifire

Commentary: Mattias Eggert, Managing Director, Unifire

The industry is changing and becoming a lot more technologically advanced. The team here at Unifire created the world’s first and only App for iOS and Android devices for the wireless remote control of our robotic nozzles (aka remote controlled monitors) as a dedication to this advancement. Technology is rapidly progressing in terms of controlling its robotic nozzle (remote controlled monitor) systems for fire fighting and numerous other applications.

You can now turn any phone or tablet into a full-featured, wireless remote control for monitor and robotic nozzle systems with InterAct technology. Eradicating the need for joysticks! We are proud to lead the industry in the further advancement of robotic nozzle technologies with the introduction of its new ONE App.

These advanced systems can be controlled and monitored from anywhere in the world, by computer or any iOS or Android device through Graphical User Interfaces (GUI’s). Users can now have the ability to control and react to an unlimited number and variety of electronic peripheral devices, including valves, lights, alarms, tank level gauges, anemometers and virtually any other electronic device. Systems can include any logic sequences, system behaviors, look and language settings desired.

These combined technologies create a seamless, bi-directional communication pathway for complete control and monitoring of CAN bus systems over any local-area network (LAN) or wide-area network (WAN). The industry is advancing and we are proud to be a part of that.

To stay up to date on the latest, trends, innovations, people news and company updates within the global fire market please register to receive our newsletter here.

Media contact

Rebecca Morpeth Spayne,

Editor, International Fire Buyer

Tel: +44 (0) 1622 823 922

Email: editor@firebuyer.com