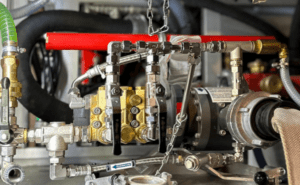

In celebration of the 160 year anniversary of Magirus, International Fire Buyer takes a look at the global technological innovations over the years In 2024, Magirus, a company deeply rooted in the firefighting industry, celebrates a monumental milestone—its 160th anniversary and the 200th birthday of its founder Conrad Dietrich Magirus. Over 160 years, this company has consistently led the way in innovation, supporting firefighters and emergency responders in their mission to protect lives and property over the decades. As we commemorate this occasion, it’s important to explore the rich history of Magirus, its groundbreaking products, and how the company has continued to shape and redefine the landscape of firefighting technology. The Visionary Behind the Company: Conrad Dietrich Magirus The story of Magirus begins with its founder, Conrad Dietrich Magirus.Born in 1824 in Ulm, Germany, C.D. Magirus set up one of the first volunteer fire brigades in Germany in his hometown of Ulm of which he was commander for 33 years A tireless researcher and ingenious inventor, he developed a wide range of new equipment that dramatically improved the options available for effective firefighting. As a result, Conrad Dietrich Magirus founded and built up a company that today remains one of the world’s leading suppliers of vehicles and equipment for firefighting and disaster control. One of his most significant early contributions was the invention of the Ulm ladder, a 14 metre high two-wheel extension ladder. This ladder was the best and safest solution to support firefighters who needed a way to access elevated areas as quickly as possible. Conrad Magirus’s invention allowed them to reach new heights, both literally and figuratively. The Ulmladder was not only a technological marvel of its time but also an example of Magirus’s commitment to solving real-world problems faced by firefighters. Magirus’s ladder became the benchmark for firefighting innovation in the 19th century and paved the way for the company’s future success. It wasn’t just a tool; it represented a fundamental shift in how firefighting could be approached.The introduction of this new technology has enabled firefighters to perform rescues from taller buildings in a safer and more efficient manner, thereby reducing response times and increasing the number of lives saved. . This innovation laid the foundation for a long history of technological advancements that Magirus would introduce over the next decades. The Rise of Motorised Fire Engines The early 20th century saw a period of rapid industrialisation across Europe and North America. Cities were expanding, and with this expansion came the growing need for faster, more reliable firefighting vehicles. Magirus quickly realised that the future of firefighting equipment lay in mechanisation, and it wasn’t long before the company transitioned from producing hand-powered tools to developing motorised fire engines. One of the most significant milestone during this time was the introduction of Magirus´s first motorized vehicle in 1916. This development marked a significant leap forward in firefighting technology, as it replaced horse-drawn carriages with a motorized vehicle, dramatically improving response times and operational efficiency for fire brigades.These early fire engine could also carry more equipment and cover greater distances.. For firefighters, this meant the ability to reach fires more quickly, tackle larger blazes, and ensure more effective rescues. In 1931, Magirus took another leap forward in the aerial rescue technology with the presentation of the first steal ladder-set for turntable ladders and many innovations in the turntable ladder technology followed in the years to come. The turntable ladder became a hallmark of Magirus’s innovation and emains a flagship product of the company’s modern firefighting vehicles. Its ability to rotate and extend made it invaluable, especially in urban environments where navigating tight spaces and accessing high-rise buildings were crucial for successful firefighting operations. The ascension to a new era In the years following the second world conflict, much of Europe needed to be reconstructed, and Magirus saw this as an opportunity to both support these efforts and Many industries were challenged by this phase, including the firefighting equipment manufacturers. Magirus was no exception, but the company persevered and played an important role in rebuilding efforts. In 1951, Magirus presented at the Frankfurt Motor Show (IAA) the DL 52+2, the highest turntable ladder in the world. The ladder set consisted of 7 sections and was fitted with a 2 meter long part ladder which could be estended manually. Ten years after the war had ended, Magirus had established itself as a global leader in the firefighting industry, fire fighting vehicle and equipments were being exported to 72 countries on all 5 continents. The Golden Age of Firefighting Technology The period from the 1960s to the 2000s marked a golden age for firefighting technology, and Magirus was at the forefront of this revolution. During these decades, the company introduced a range of new products and innovations that transformed firefighting as we know it today. One of the key advancements was the introduction of highly specialised vehicles for different firefighting scenarios. For example, Magirus designed its its first ARFF aircrash rescue and firefighting vehicle, which was equipped with foam systems and high-capacity water pumps to handle runway fires involving jet fuel. At the same time, the company developed vehicles for tackling wildfires in remote forested areas, incorporating features like all-terrain capabilities and water tanks with extended reach. By the 1980s, Magirus presented its famous AluFire technology, the revolutionary aluminum superstructure composition and its firs computer controlled turntable ladder. The 2000s saw a proliferation of innovative turntable ladder technology. Following the introduction of the first articulated turntable ladder with a telescopic arm, the first turntable ladder with Single Extension technology was unveiled in 2012. This was followed by the M42L-AS, which was hailed as the “world’s highest articulated ladder.” In a similar vein, the heavy-duty ladder truck was introduced a few years later. In 2015, a further record was set with the M68L turntable ladder, which was designated as the world’s highest turntable ladder. Robotics and Digital Innovation As the world entered the 21st century, firefighting faced new challenges and opportunities,