Per Aredal, International Sales Director, Firemiks AB sits down with International Fire Buyer to explain the differences in viscosities in proportioners and the transition to SFFF

Please introduce yourself and give a brief insight into Firemiks?

I am the International Sales Director at Firemiks AB, originally established in 1979 as a Swedish family-owned business, now operated by the third generation in collaboration with our strong industrial partners. Over the years, our focus has been on developing, manufacturing, and distributing our proprietary water-driven volumetric pump proportioning systems globally. We pride ourselves on offering custom solutions tailored to the unique needs of each client’s project while also delivering standardized models that meet rigorous international certifications, such as FM Approvals.

Can you elaborate on the range of viscosities your proportioners handle, and the transition from AFFF to SFFF?

FM approval designates our system as the “Variable Viscosity Pump Proportioner,” meaning that if the specified minimum and maximum flow rates in the data sheet are followed, Firemiks can accommodate viscosity changes across a wide flow and pressure range. The dosing remains within the approved tolerance limits specified in the standards (e.g., 3.0-3.9%). This offers the significant advantage of eliminating the need for recalibration whenever there is a change in concentrate or viscosity – unlike bladder tanks, which often require recalibration and create critical downtime during replacement.

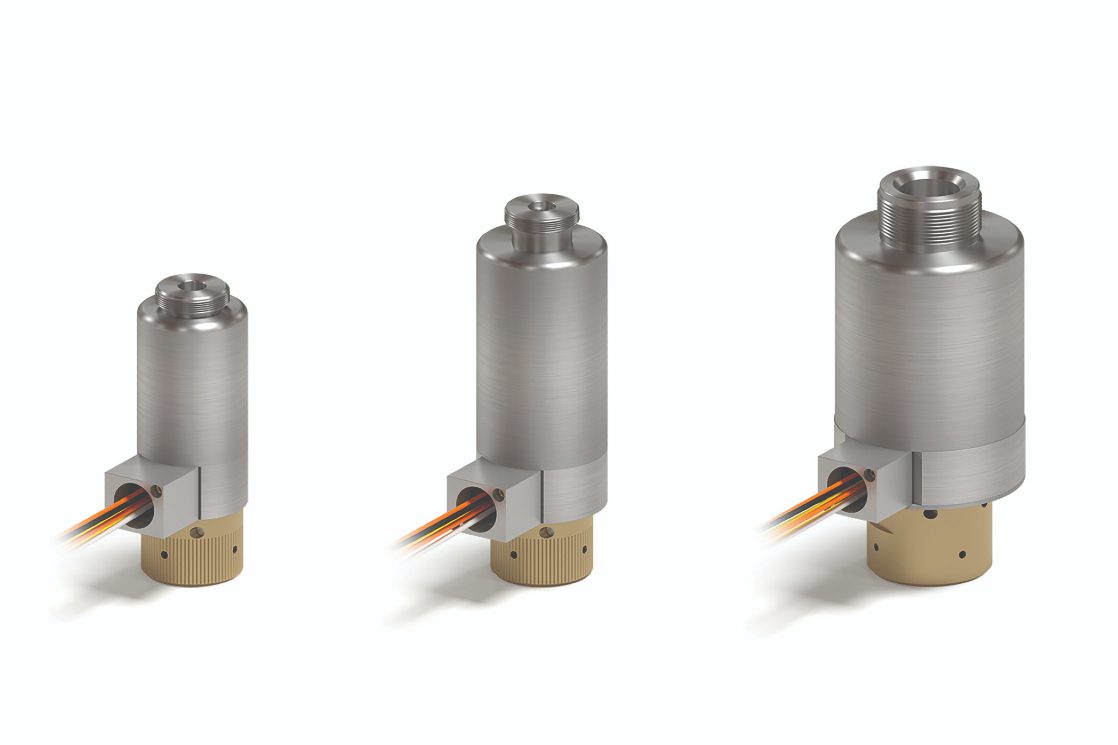

The FM approval we have received (Standard: 5130 – May 2021) for eight of our 3% models, across three flow sizes -1800, 2400, and 4000 lpm – confirms that the FM-approved Firemiks units provide accurate dosing and can handle concentrates ranging from 1 cP to high-viscosity concentrates (up to 6422 cP at a shear rate of 5 1/s).

This means that if a concentrate has a shear rate curve that falls below or aligns with the specified figures, it will perform well with our FM-approved Firemiks models. This applies especially to the new generation of fluorine-free SFFF concentrates, which are non-Newtonian and have these high static viscosities.

To ensure optimal dosing performance at maximum viscosity for the three FM-approved sizes, the required concentrate delivery hose/pipe dimensions and height are well defined on the data sheet, removing the guesswork from the design.

For even higher viscosities than our FM Approved line, we also offer gear pump models that can handle these as the rotating gears have a continuous motion, removing the reciprocating motions through the whole shear curve as is the case with piston pumps.

How does the Dosing/Return valve contribute to environmental sustainability and cost savings during testing? With the optional Dosing/Return valve (DRV) placed in Return position it directs the concentrate back to the tank and allows for easy and recurring dosing testing of the system, without generating foam solution. This feature gives substantial savings over many years. No consumption of concentrate and no cost for cleaning or destruction of the solution after the test.

One example: an 8000 lpm unit with 3% dosing rate with 2 tests/year at max speed for 2 minutes. 8000 lpm x 2 min x 3% = 480 Lit of foam concentrate x 2 times = 960 Lit at an average cost of 4 EUR/Lit = 3 840 EUR.- in saved concentrate cost/year, without calculating the cost for cleaning and destruction.

Apart from creating the long-time economic benefits, the optional DRV makes it easier to follow environmental guidelines and regulations. A Pressure Relief valve (PRV) is always included with this DRV option to ensure that no over-pressure is created in the Firemiks, if a valve in the return line back to concentrate tank is closed by mistake.

To read more exclusive articles and latest news, see our last issue here.

Never miss a story… Follow us on:

LinkedIn: International Fire Buyer

Twitter (X): @Firebuyer

YouTube: @FireBuyerTV

Media Contact

Rebecca Spayne Managing Editor, International Fire Buyer

Tel: +44 (0) 1622 823 920

Email: [email protected]